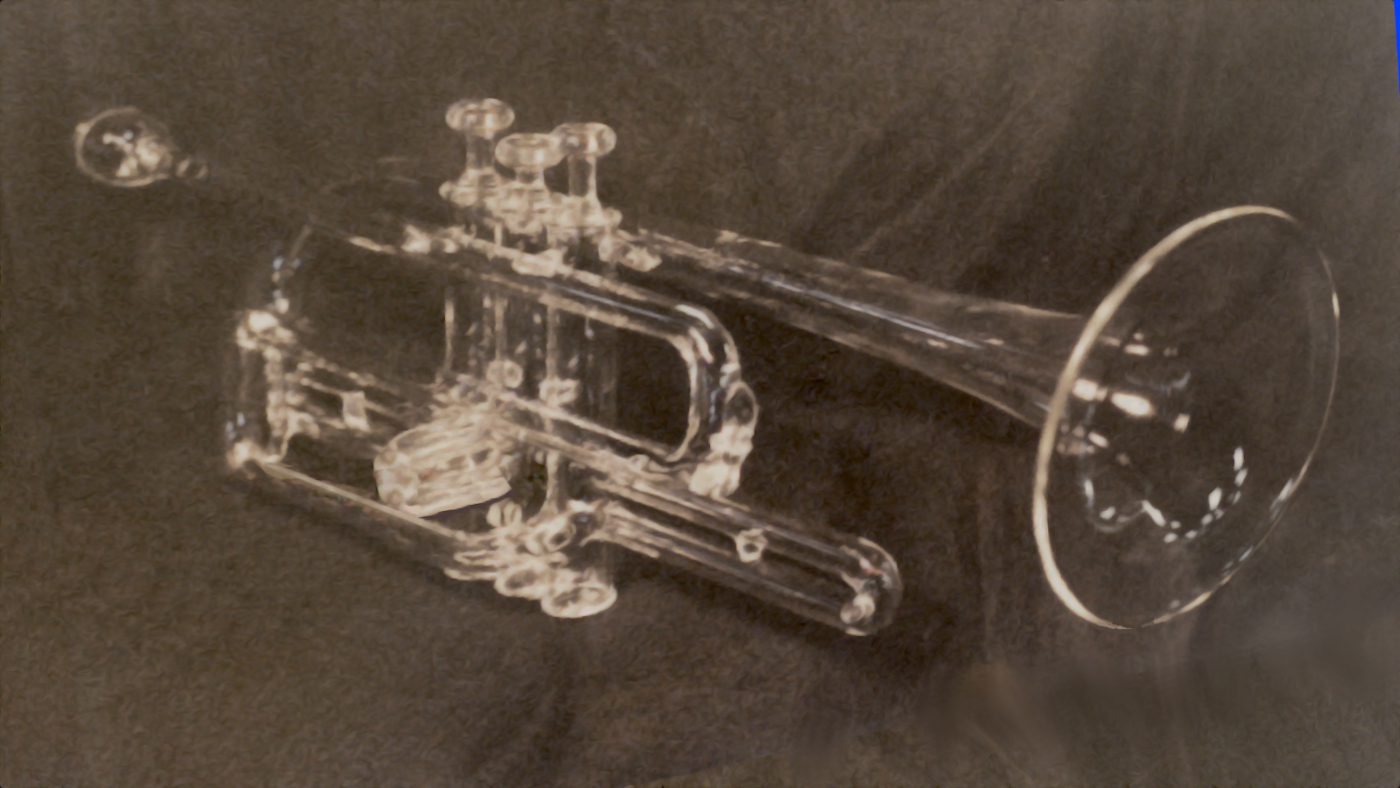

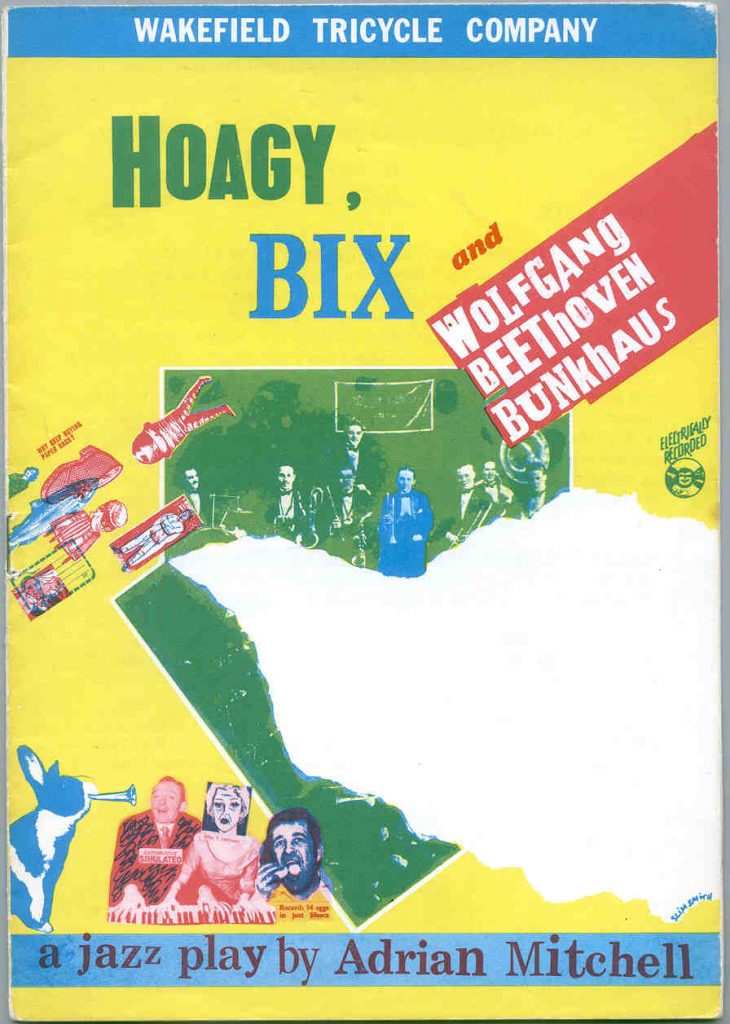

I was coming to the end of my first year as a scientific glassblower. Thurston LeVay, the owner of Glass Instruments, came into the shop and talked with the shop’s leadman, John Smith. I saw John shake his head and Thurston went to the second glassblower’s bench and talked with Jimmy Sato. They both looked at me and Thurston walked back and told me there was a guy in his office that wanted a trumpet made from glass. It was for a play about Bix Beiderbecke, a coronet player actually, and he asked if I could make one.

I had met Thurston five years before, when we were both taking off-hand glassblowing lessons from M. Rhys Williams at his Cactus Glassworks in Claremont, California. Rhys had come to my mom’s workplace looking for fire brick to build a new glassblowing studio in Pitzer College, one of the Claremont Colleges. My mom was the office manager of Pyro Engineering, a small firm that designed and repaired furnaces to make steel (back when we made steel in America), and sold fire resistant brick and mortar and casting materials. I was taking glassblowing classes at Rio Hondo Junior College, so she got a card from Rhys and gave it to me the next time I stopped by to visit.

Traditionally, glassblowing is done in teams. You might have seen it at a fair or on PBS. One person gathers glass from the furnace on a steel blowpipe, while another is adding color or decorating another glass bubble. The gaffer (an affectionate term for grandfather in Italian) typically sits at the bench and finishes the pieces before handing them to the ‘boy’ that takes them off the blowpipe, puts them away in the 900 degree annealing oven, cleans the remaining bits of glass off the pipes and punty rods and returns them to the rack beside the furnace to pre-heat. It is a continuous process; All members of the gaffer’s team are continuously doing their jobs as the finished pieces accumulate in the annealer. They are cooled slowly overnight to relieve the stresses induced by shaping the glass with steel tools and reheating to continue working on a piece.

In 1962, Harvey Littleton gathered a group of ceramic artists at the Toledo Museum of Art in Ohio. He had an idea that they would build a little furnace and blow glass. For fun and as a learning adventure. At that time the only people, worldwide, that had access to molten glass were the workers in glass factories. Whether they were making plate glass for architectural glazing, running machines to make bottles and light bulbs, or making the glassware used in academic and commercial laboratories, only professionals had access to hot glass. Harvey Littleton had a retired glassblower, Harvey Leafgreen stop by and show the workshop participants how to gather the glass, start the bubble and give it some shape. Several of the ceramicists went back to their colleges and studios, built small glass furnaces and started to learn more about glassblowing. That was the start of the American Studio Glass Movement.

In glass studios, unlike factories, there is usually just the glass artist (and perhaps an assistant or two) doing all the jobs required to produce a piece. Over the years many unique processes have been created and there has been an explosion of glass art around the world; from the smallest art museums to Las Vegas casinos, people have been enjoying and collecting glass art. Rhys Williams is one of those glass artists. Know for his painterly use of color on the vases and bowls he blows by himself, he has also been teaching at local colleges for over forty years. To help support his private studio in his early days he gave glassblowing lessons and to lower the cost to the student and teach teamwork, two students were scheduled at the same time. That’s how I met Thurston LeVay.

Recognizing that most glass artists were upper middle class was the first time I realized that being working class limited one’s life choices. I didn’t have a trust fund to help me go to art school or start a glass studio (the most expensive art form because of the energy required), so I looked for work in glass shops. I repeatedly asked Thurston for a job, but he told me that they didn’t hire anyone without experience. Catch 22! While managing the local head shop (I think they are called smoke shops today), I met Dick, the owner of the LAPD. Not the Los Angeles Police Department but the LA Pipe Distributor. Through him I met Gene, the owner of the Doobie Incense Company, who distributed incense and made glass pipes and funnels for aficionados of hash oil. This was before drug paraphernalia became illegal in California. I convinced Gene to hire me as a glassblower and soon I was blowing 200 hash oil pipes an hour! I quickly sent up a torch in my kitchen (don’t tell the fire marshall), and at 5 cents apiece I was making ten dollars an hour. It was the ‘70s and I could easily make my monthly rent in a day! When I applied for a job in a factory a couple years later, I could honestly say that I had years of experience with Pyrex glass. Not that it mattered, my next job was making quartzware for the semi-conductor industry. Purity being crucial, this glassware is made from Pure Fused Quartz (PFQ) which requires a hydrogen/oxygen flame to reach the 4,000 degrees necessary to work it. This is the same flame that launches the space shuttle and makes quartz work the most dangerous form of glassblowing. And that’s how I gathered enough experience to get a job at Glass Instruments.

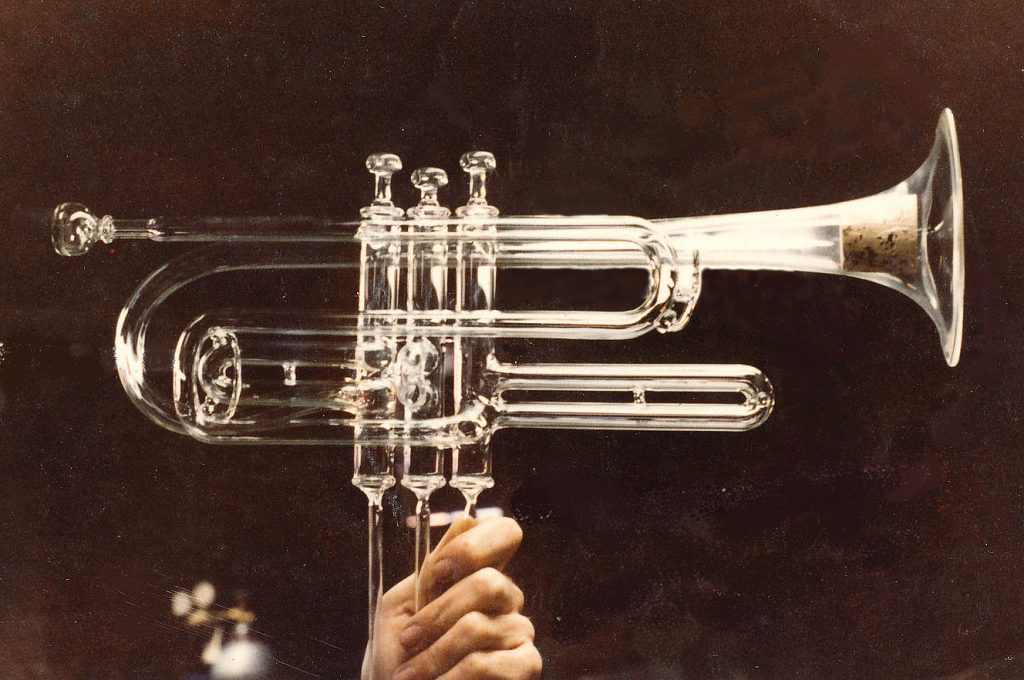

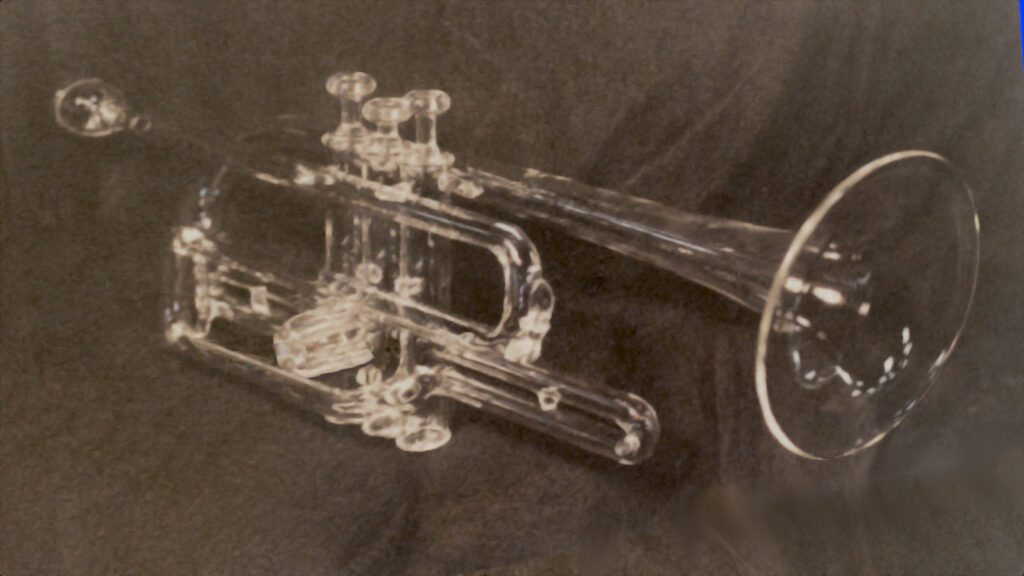

I told Thurston I could make the glass coronet and he asked me how long I thought it would take. From my vantage point of being retired, I can see that he was playing with me, but I told him I could make it in a day. Estimating custom work is the hardest part of any small business and I’ve learned to multiply my best guess by two to cover the inevitable unforeseen challenges. Thurston knew that better than anyone, but he let me try to make it. The set designer for the Mark Taper Forum brought a real coronet in as a pattern, I have no idea what Thurston charged him for the glass one. I took some measurements and went to work. The first day went well but I wasn’t finished. Hank, the shop manager, was an engineer and stiff old Yankee that didn’t like longhairs. He started needling me the next morning, reminding me that I had estimated I would only take one day. John, the lead glassblower just smiled but I knew everything was OK when Thurston’s son (the sales manager) came into the shop and started taking pictures. By noon the coronet was finished and put in the annealing oven.

That’s the day I learned I could hold my own in any scientific glass shop.

A few days later the designer picked up his prop and left me two tickets to the show.

I found these on the internet:

“The following is an almost verbatim transcription of an account kindly provided to me by Richard M. Sudhalter.

The Taper production in Los Angeles came some months later. The stage band was myself on cornet, Dave Frishberg singing and playing piano, Bob Reitmeier on clarinet and alto, Howard Alden (age 22) on banjo and guitar, Putter Smith (younger brother of Carson Smith) on bass, and Dick Berk on drums. The cast included the singer-cabaret artist Amanda McBroom. Mark Robman worked out an interesting idea for staging the musical sequences: every time the Bix character, played by Harry Groener, had to play some cornet, he would stand, horn at mouth, in the spotlight, facing the audience; I would stand, in darkness, back-to-back with him, but costumed identically. Then we would simply revolve, as if on a pedestal, bringing me into the spotlight and him into shadow. I’d play the solo – I remember doing “Singin’ the Blues” and “I’m Comin’ Virginia,” among others – then we’d revolve back, and I’d melt into the darkness off stage while Groener carried on with his lines. The musical side of the show got mostly rave reviews, but Mitchell’s play took a critical pasting. Unfairly, I thought: he’d tried, very imaginatively, to bring off a difficult concept, blending the Weltschmerz of the Bunkhaus humor (even casting some of the episodes as puppet-show plays within the play) with the Beiderbecke tragedy, all against the Carmichael coming-of-age motif. There were things that didn’t work, sure – but I thought then, and still do, that it was a very ambitious undertaking and deserved better treatment than it got.” http://bixography.com/inforrelated.htm#HoagyBix,Bunkhaus.

A few days after my 25th birthday, my girlfriend and I saw Hoagy, Bix and Wolfgang Beethoven Bunkhouse in the Mark Taper Forum at the Los Angeles Music Center. I’d been to dozens of live theater shows, including musicals, but I’d never seen anything like a lead musician, standing behind the actor playing a musician, rotating into the spotlight for solos. We waited to see my glass coronet, and when one of the characters said Bix’s tone was as clear as if it were from a crystal coronet, the musician rotated into the shadows as ‘Bix Beiderbecke’ came into the spotlight playing a ‘crystal’ coronet. That was the moment that I realized that not only could I make anything out of glass, but I could participate in the ‘arts’ without going to an expensive private art college.

I have always wondered where the crystal coronet went after the house went dark. Apparently, there was never another production mounted.